Links:

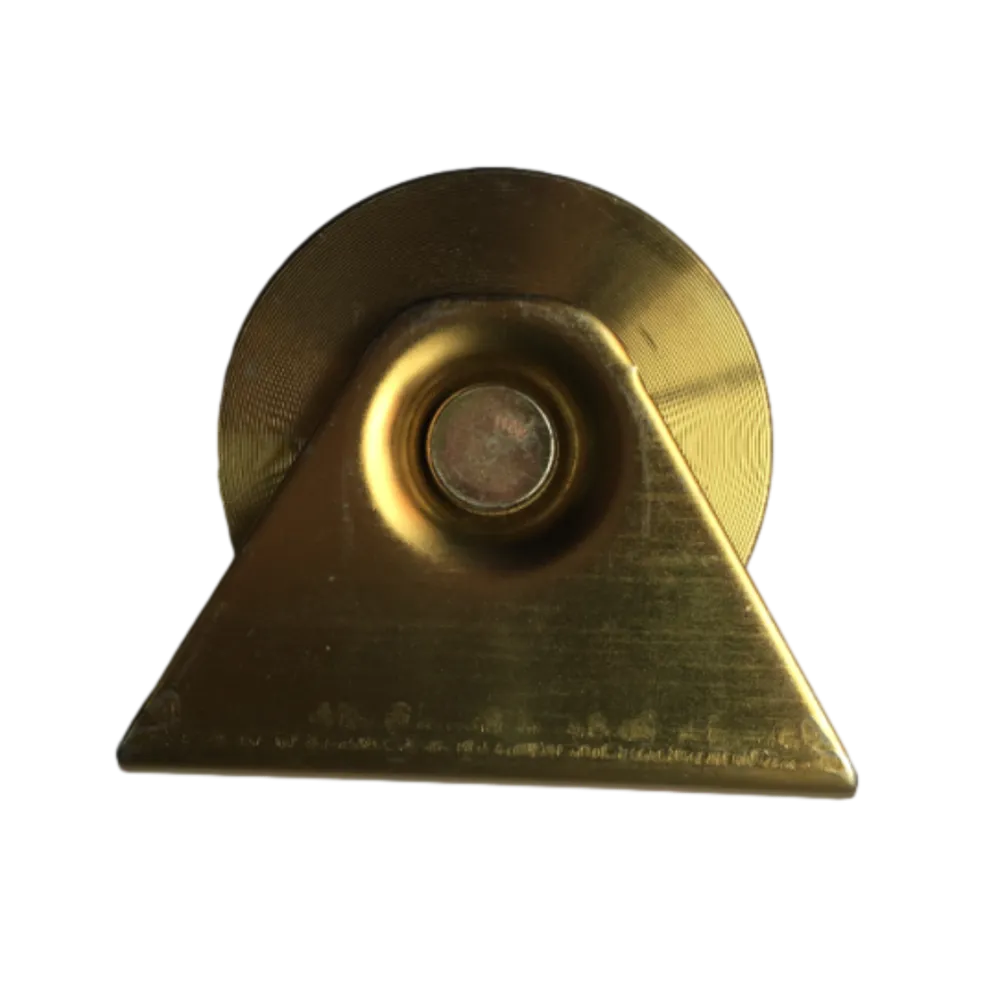

Types of Sliding Door Wheels

Members or rails are horizontal elements that make up some main structural components of iron fences. These components are important for your fencing as they essentially help to hold the fence together. Rails run parallel to the ground and exist to connect fence panels to the posts. Additional horizontal members may be a part of the fence’s design in order to incorporate decorative elements or panels into your wrought iron fence.

Cast iron is primarily distinguished by its ability to be molded into complex shapes and structures, thanks to its casting properties. This characteristic makes it a preferred choice for creating intricate components that would be difficult or impossible to manufacture with other materials. The process of casting involves heating the iron to a molten state, pouring it into a mold, and allowing it to solidify, thus forming the desired component.In conclusion, wrought iron railing panels are more than just functional barriers; they are living tributes to artisanal skill and a nod to the past. They bring a sense of grandeur and security to any space, making them a popular choice for those seeking a blend of form and function. Whether enhancing the grandeur of a historic building or adding a touch of elegance to a modern home, wrought iron railing panels remain a distinctive and cherished element in the world of architecture and design.

In addition to their functional uses, metal leaves in welding also have significant cultural and artistic implications. They are often seen in sculptures, architectural features, and even in custom automotive work, reflecting a blend of traditional craftsmanship and modern technology. These metal leaves, when skillfully welded, can transform a simple structure into a work of art, narrating stories through their intricate designs and patterns.

One of the key benefits of adjustable screen door rollers is their ability to adapt to different door sizes. Whether you have a standard-size screen door or a custom-made one, adjustable rollers can be easily adjusted to ensure a perfect fit. This not only helps to prevent any unwanted friction or sticking when opening and closing the door but also prolongs the lifespan of the rollers themselves. Furthermore, stainless steel barn door handles are easy to install and can be a do-it-yourself project for homeowners with basic tools and skills. With just a few simple steps, you can upgrade the look of your doors and enhance the overall aesthetic of your home. With the wheels loose, gently lift the door slightly off the track so that you can access the wheel assembly

Step 7 Test Your Repair

Maintaining decorative wrought iron fence panels is relatively simple. A regular cleaning with a mild detergent and water is usually all that is needed to keep the panels looking their best. Additionally, a coat of rust-resistant paint or sealant can help protect the panels from the elements and prolong their lifespan.

When it comes to design flexibility, aluminium window profiles truly excel. They can be easily customized to fit any size or shape of window, allowing you to achieve the exact look and feel you want for your home or commercial space. Whether you prefer a classic, traditional style or a sleek, modern look, there is an aluminium window profile to suit your needs. Overall, rollers for aluminum sliding windows may be small in size, but they play a significant role in the functionality, energy efficiency, and longevity of the windows. By selecting high-quality rollers and ensuring proper maintenance, homeowners can enjoy smooth and effortless operation of their sliding windows for years to come. Investing in quality rollers is a smart decision that can improve the comfort and performance of any home. In conclusion, the aluminium window frame section is more than just a structural element; it is a testament to the harmonious integration of form, function, and sustainability in contemporary building design. Its robustness, versatility, and energy-saving properties make it a standout choice for homeowners and builders. Whether it's a modern high-rise or a traditional cottage, aluminium window frame sections promise to elevate both the look and performance of any building they grace.

The benefits of using cast iron for spears lie in its inherent properties. Cast iron, known for its excellent castability, is resilient and suitable for manufacturing sharp, sturdy spearheads that can withstand the rigors of battle. The material's high carbon content contributes to its hardness, allowing for effective penetration without easily blunting. Moreover, the casting process enables the creation of complex shapes that traditional methods cannot replicate, leading to innovative spear designs tailored for specific combat contexts.

cast iron spear

After replacing the wheels, carefully lower the door back onto the track. Test the door's movement to ensure the new wheels are functioning properly. If the door still doesn't glide smoothly, you might need to adjust the tension or alignment of the wheels, or check for any obstructions in the track. Another benefit of wrought iron baskets is their low maintenance requirements. Unlike baskets made of other materials, such as wicker or wood, wrought iron baskets are not susceptible to mold, mildew, or insect damage Unlike baskets made of other materials, such as wicker or wood, wrought iron baskets are not susceptible to mold, mildew, or insect damage

Unlike baskets made of other materials, such as wicker or wood, wrought iron baskets are not susceptible to mold, mildew, or insect damage Unlike baskets made of other materials, such as wicker or wood, wrought iron baskets are not susceptible to mold, mildew, or insect damage

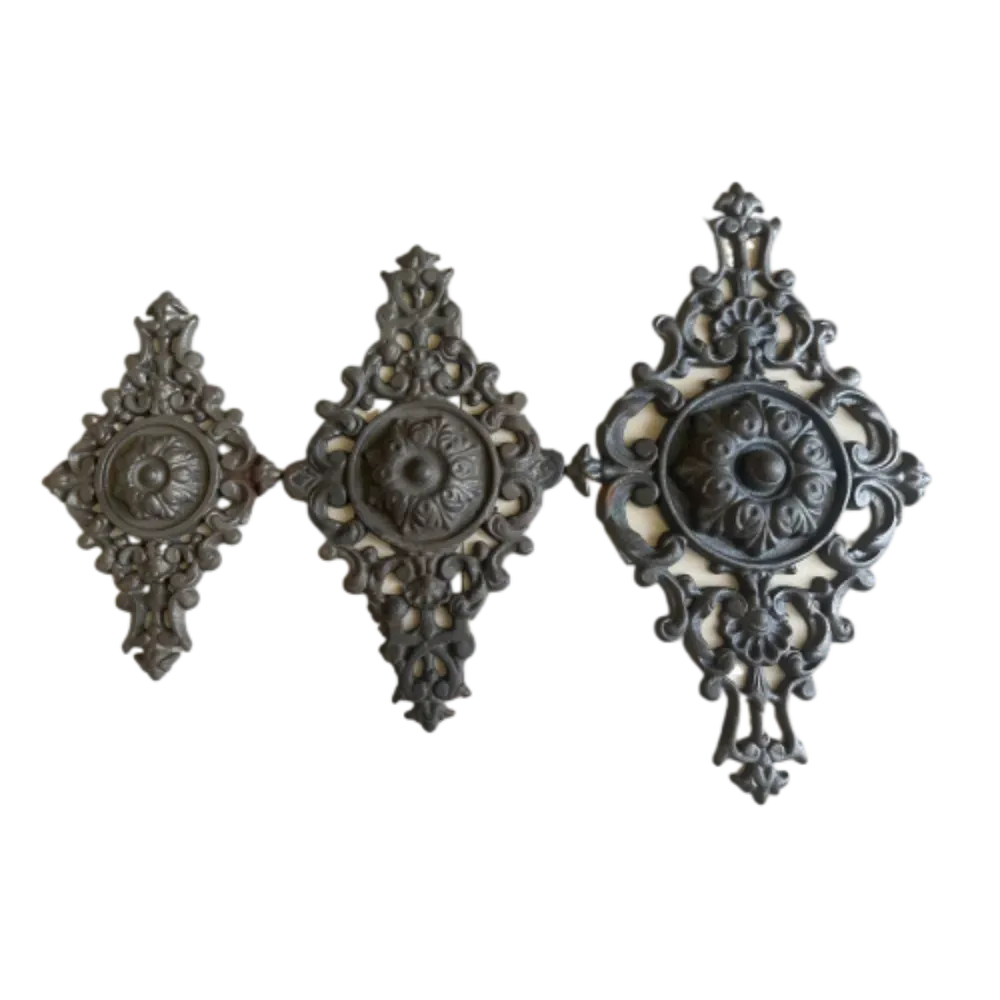

Unlike baskets made of other materials, such as wicker or wood, wrought iron baskets are not susceptible to mold, mildew, or insect damage Unlike baskets made of other materials, such as wicker or wood, wrought iron baskets are not susceptible to mold, mildew, or insect damage wrought iron basket. They can be easily cleaned with a damp cloth or sponge, and their durable finish ensures that they will remain looking like new for years to come. One such company, committed to excellence in this field, is known for its innovative designs, superior quality, and exceptional customer service. Their products, crafted with precision, reflect a deep understanding of ergonomic principles and the latest technological advancements. Whether it's a sleek, modern apartment or a traditional country house, their hardware range caters to diverse architectural styles, ensuring seamless integration. In historical contexts, cast iron post collars were symbols of durability and strength, often used in grandiose buildings such as banks, courthouses, and mansions. They conveyed a message of stability and permanence, reassuring visitors and occupants alike. Today, while their presence may be less common, they still retain an undeniable aesthetic value that is highly sought after by designers looking to imbue a sense of history and timelessness into modern structures Today, while their presence may be less common, they still retain an undeniable aesthetic value that is highly sought after by designers looking to imbue a sense of history and timelessness into modern structures

wrought iron basket. They can be easily cleaned with a damp cloth or sponge, and their durable finish ensures that they will remain looking like new for years to come. One such company, committed to excellence in this field, is known for its innovative designs, superior quality, and exceptional customer service. Their products, crafted with precision, reflect a deep understanding of ergonomic principles and the latest technological advancements. Whether it's a sleek, modern apartment or a traditional country house, their hardware range caters to diverse architectural styles, ensuring seamless integration. In historical contexts, cast iron post collars were symbols of durability and strength, often used in grandiose buildings such as banks, courthouses, and mansions. They conveyed a message of stability and permanence, reassuring visitors and occupants alike. Today, while their presence may be less common, they still retain an undeniable aesthetic value that is highly sought after by designers looking to imbue a sense of history and timelessness into modern structures Today, while their presence may be less common, they still retain an undeniable aesthetic value that is highly sought after by designers looking to imbue a sense of history and timelessness into modern structures Today, while their presence may be less common, they still retain an undeniable aesthetic value that is highly sought after by designers looking to imbue a sense of history and timelessness into modern structures Today, while their presence may be less common, they still retain an undeniable aesthetic value that is highly sought after by designers looking to imbue a sense of history and timelessness into modern structures

Today, while their presence may be less common, they still retain an undeniable aesthetic value that is highly sought after by designers looking to imbue a sense of history and timelessness into modern structures Today, while their presence may be less common, they still retain an undeniable aesthetic value that is highly sought after by designers looking to imbue a sense of history and timelessness into modern structures cast iron post collars. As the morning turns to afternoon, the focus shifts to Liatinyová street, a trendy boulevard known for its eclectic mix of shops, cafes, and galleries. Here, the festival takes on a more contemporary vibe, blending the old with the new. Street performers dazzle crowds with acrobatic displays and live music, while food trucks offer an array of international cuisines, reflective of Prague's cosmopolitan flair. Art lovers wander through pop-up exhibitions showcasing the works of emerging artists, their canvases and sculptures adding splashes of color against the urban landscape Art lovers wander through pop-up exhibitions showcasing the works of emerging artists, their canvases and sculptures adding splashes of color against the urban landscape

cast iron post collars. As the morning turns to afternoon, the focus shifts to Liatinyová street, a trendy boulevard known for its eclectic mix of shops, cafes, and galleries. Here, the festival takes on a more contemporary vibe, blending the old with the new. Street performers dazzle crowds with acrobatic displays and live music, while food trucks offer an array of international cuisines, reflective of Prague's cosmopolitan flair. Art lovers wander through pop-up exhibitions showcasing the works of emerging artists, their canvases and sculptures adding splashes of color against the urban landscape Art lovers wander through pop-up exhibitions showcasing the works of emerging artists, their canvases and sculptures adding splashes of color against the urban landscape Art lovers wander through pop-up exhibitions showcasing the works of emerging artists, their canvases and sculptures adding splashes of color against the urban landscape Art lovers wander through pop-up exhibitions showcasing the works of emerging artists, their canvases and sculptures adding splashes of color against the urban landscape

Art lovers wander through pop-up exhibitions showcasing the works of emerging artists, their canvases and sculptures adding splashes of color against the urban landscape Art lovers wander through pop-up exhibitions showcasing the works of emerging artists, their canvases and sculptures adding splashes of color against the urban landscape platňa šporáková, liatinová.

platňa šporáková, liatinová. The biggest difference between these two types of fences is the material they are made from.

cast iron designs.

Top hung windows opening outwards

In addition to their durability, door roller bearings also provide excellent support and stability for the door. The smooth operation of these bearings ensures that the door remains in proper alignment and does not wobble or sag. This not only enhances the appearance of the door but also helps to extend its overall lifespan. But what of the treasures that lay within its confines? They are as varied as the individuals who rely upon this miniature fortress. For some, it safeguards precious family heirlooms—timeworn photographs, yellowed letters, and antique jewelry that glint with memories rather than mere gemstones. For others, it may hold the mundane yet vital—keys, documents, or even the modern digital doppelgänger, a USB drive laden with critical data For others, it may hold the mundane yet vital—keys, documents, or even the modern digital doppelgänger, a USB drive laden with critical data For others, it may hold the mundane yet vital—keys, documents, or even the modern digital doppelgänger, a USB drive laden with critical data For others, it may hold the mundane yet vital—keys, documents, or even the modern digital doppelgänger, a USB drive laden with critical data

For others, it may hold the mundane yet vital—keys, documents, or even the modern digital doppelgänger, a USB drive laden with critical data For others, it may hold the mundane yet vital—keys, documents, or even the modern digital doppelgänger, a USB drive laden with critical data small steel lock box.

small steel lock box. It is ideal for specific aluminum components prone to extreme wear environments and applications. You may also consider it in window and door applications, which require enhanced electrical insulation.

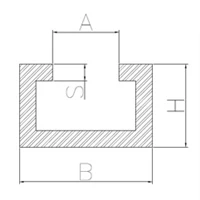

You should also consider the size of the rollers when purchasing sliding door rollers for sale sliding door rollers for sale. The size of the rollers will depend on the width and thickness of your door, as well as the size of the track. Make sure to measure your door and track accurately to ensure that the rollers you purchase will fit properly. Regular maintenance is key to prolonging the lifespan of sliding door wheels. Dust and debris can accumulate in the track, causing the wheels to roll imperfectly. Periodically cleaning the tracks and lubricating the wheels with silicone spray can prevent premature wear.

sliding door rollers for sale. The size of the rollers will depend on the width and thickness of your door, as well as the size of the track. Make sure to measure your door and track accurately to ensure that the rollers you purchase will fit properly. Regular maintenance is key to prolonging the lifespan of sliding door wheels. Dust and debris can accumulate in the track, causing the wheels to roll imperfectly. Periodically cleaning the tracks and lubricating the wheels with silicone spray can prevent premature wear. So, when it comes to wrought iron vs. aluminum fences and steel fences, which option is right for you?

4. Easy Maintenance Replacing worn-out roller wheels is a simple and cost-effective process that can be done without the need for professional assistance.